From idea to a manufacturable and cost-efficient product.

Engineering & design of components

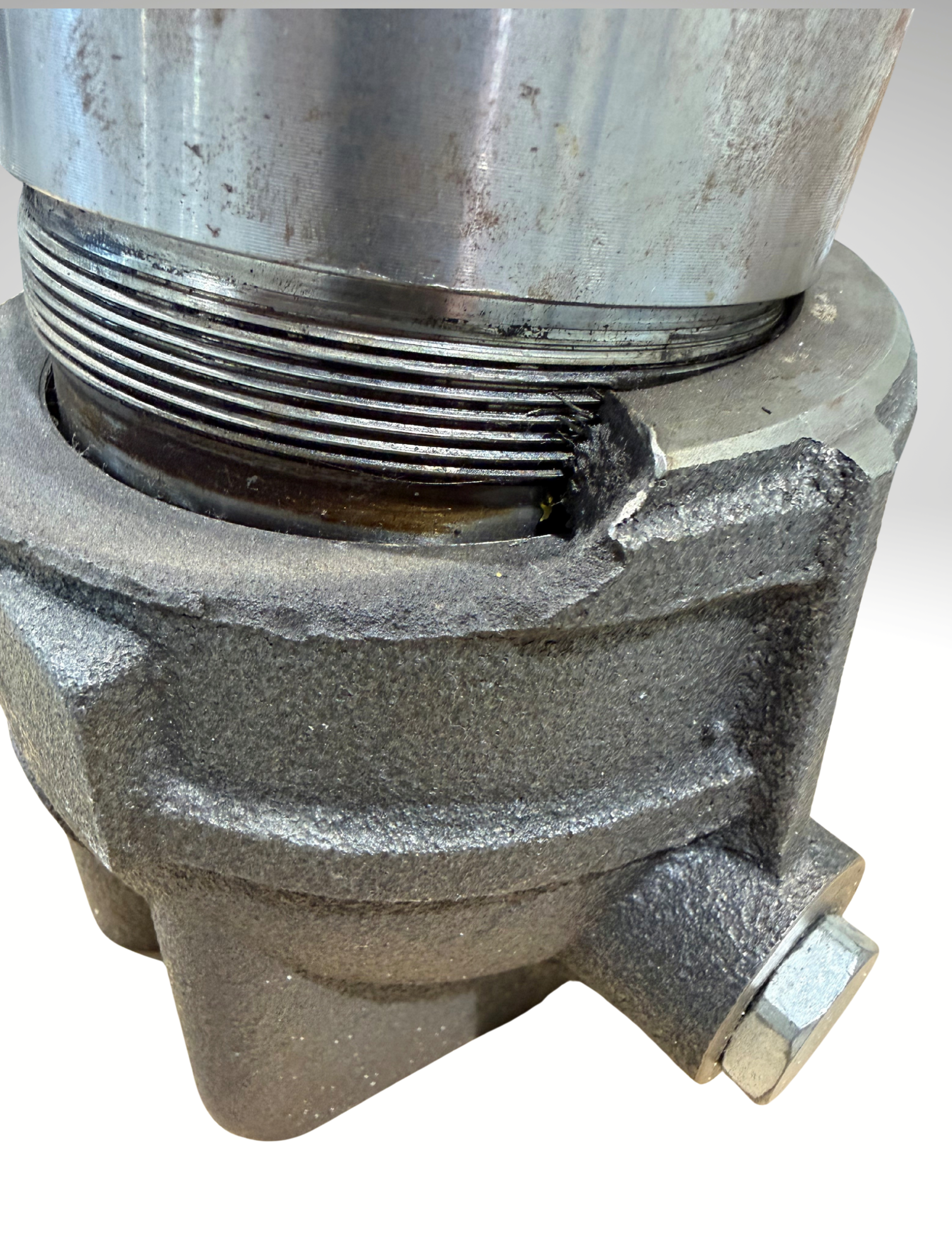

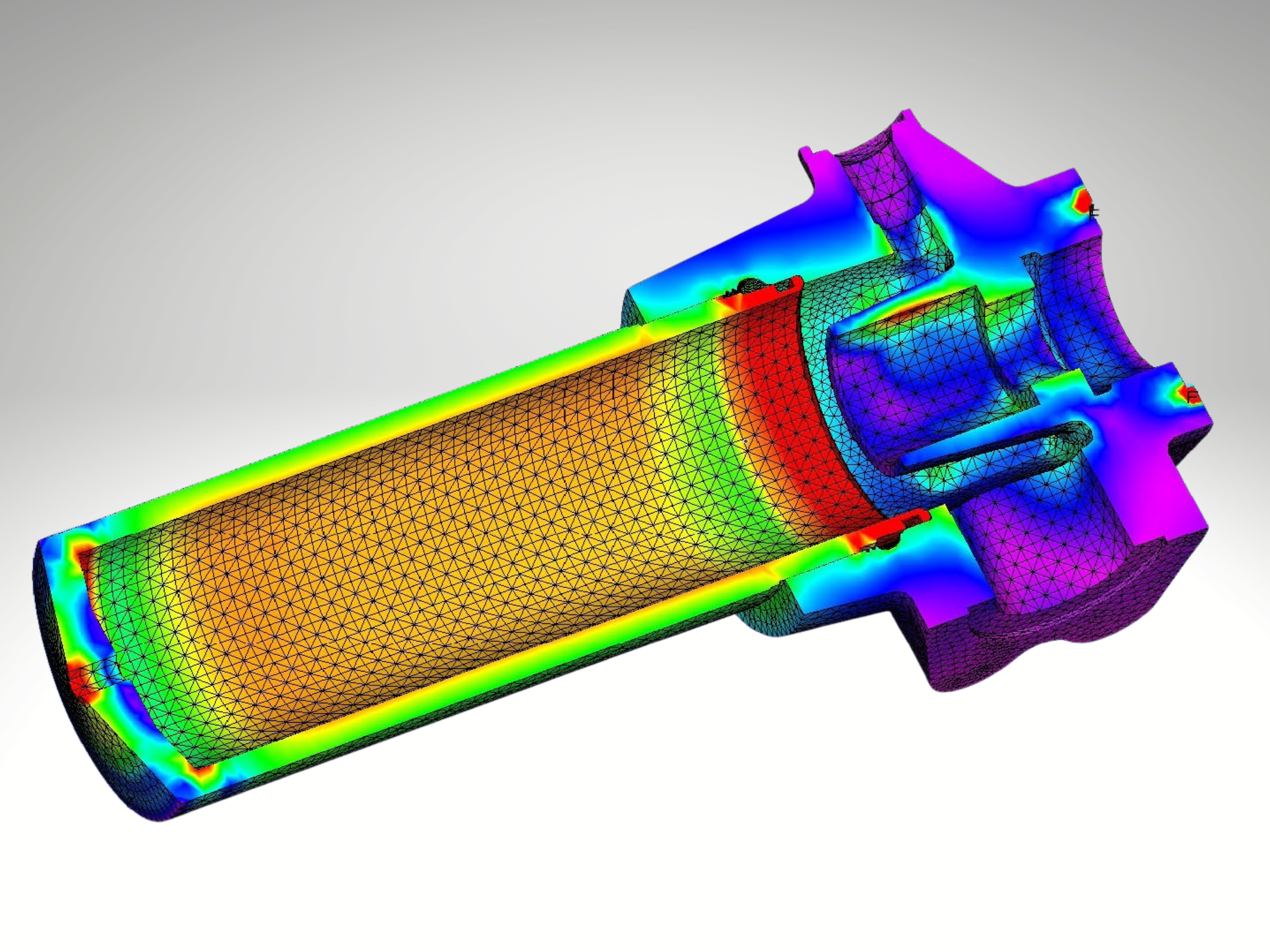

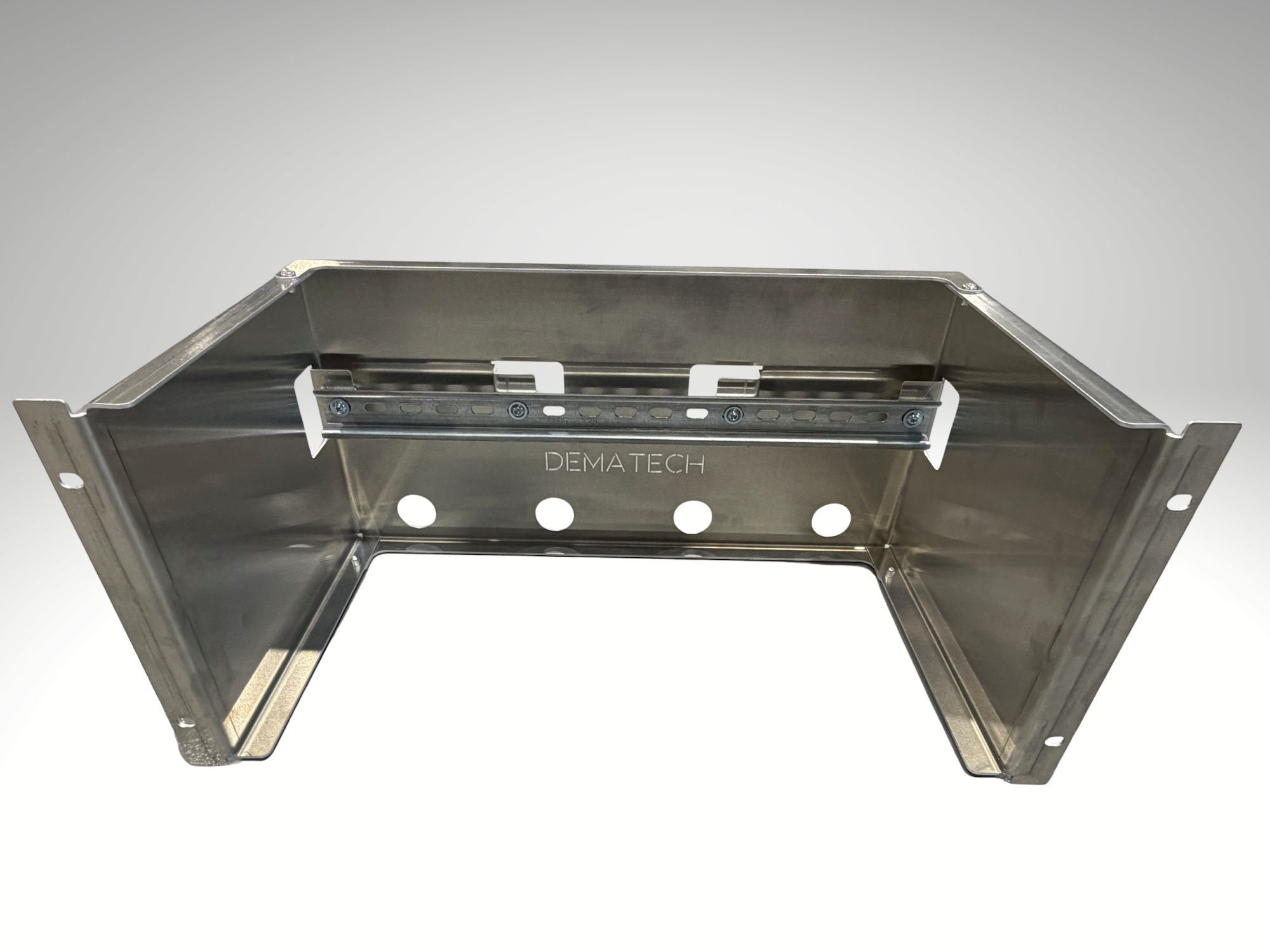

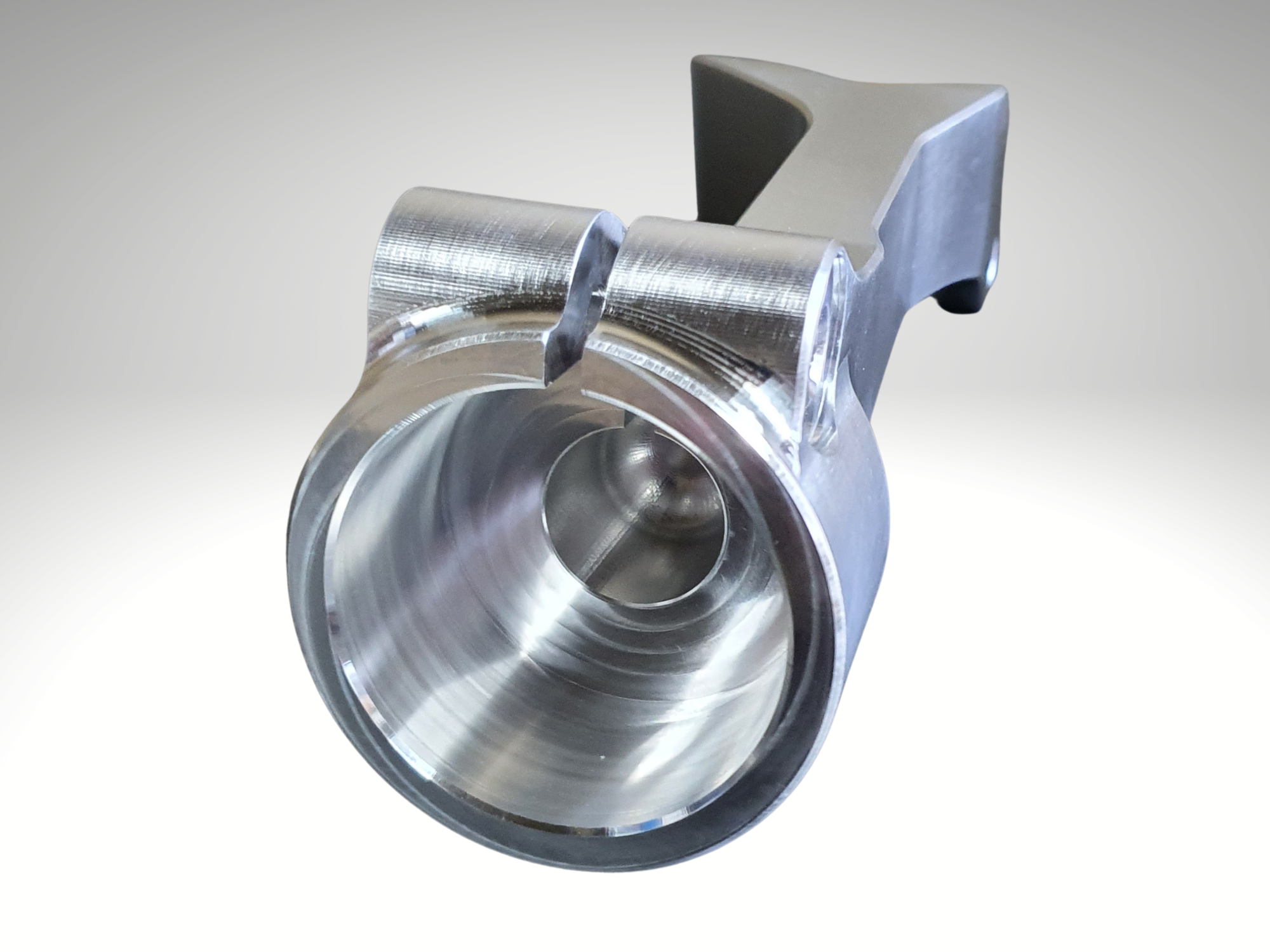

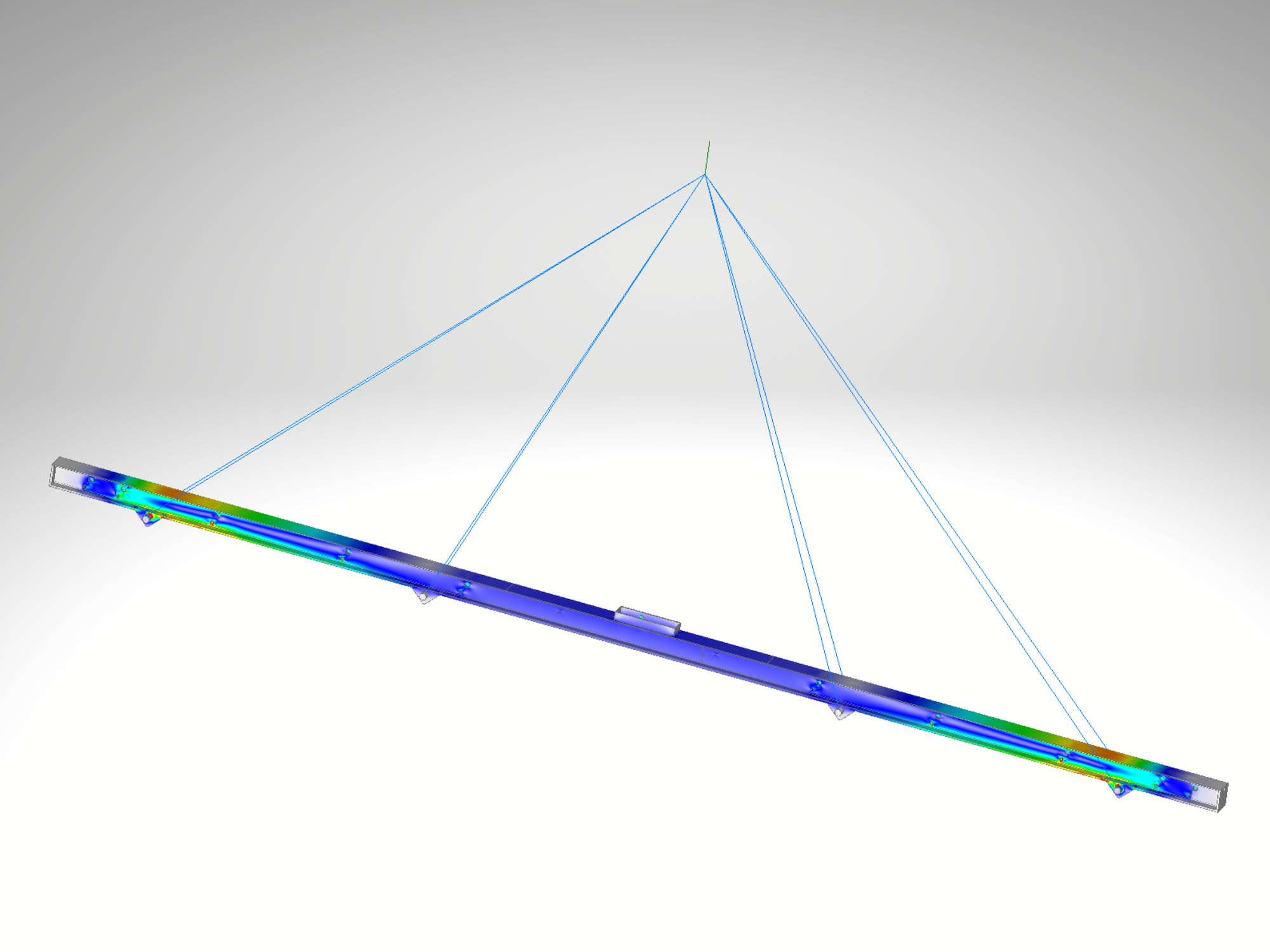

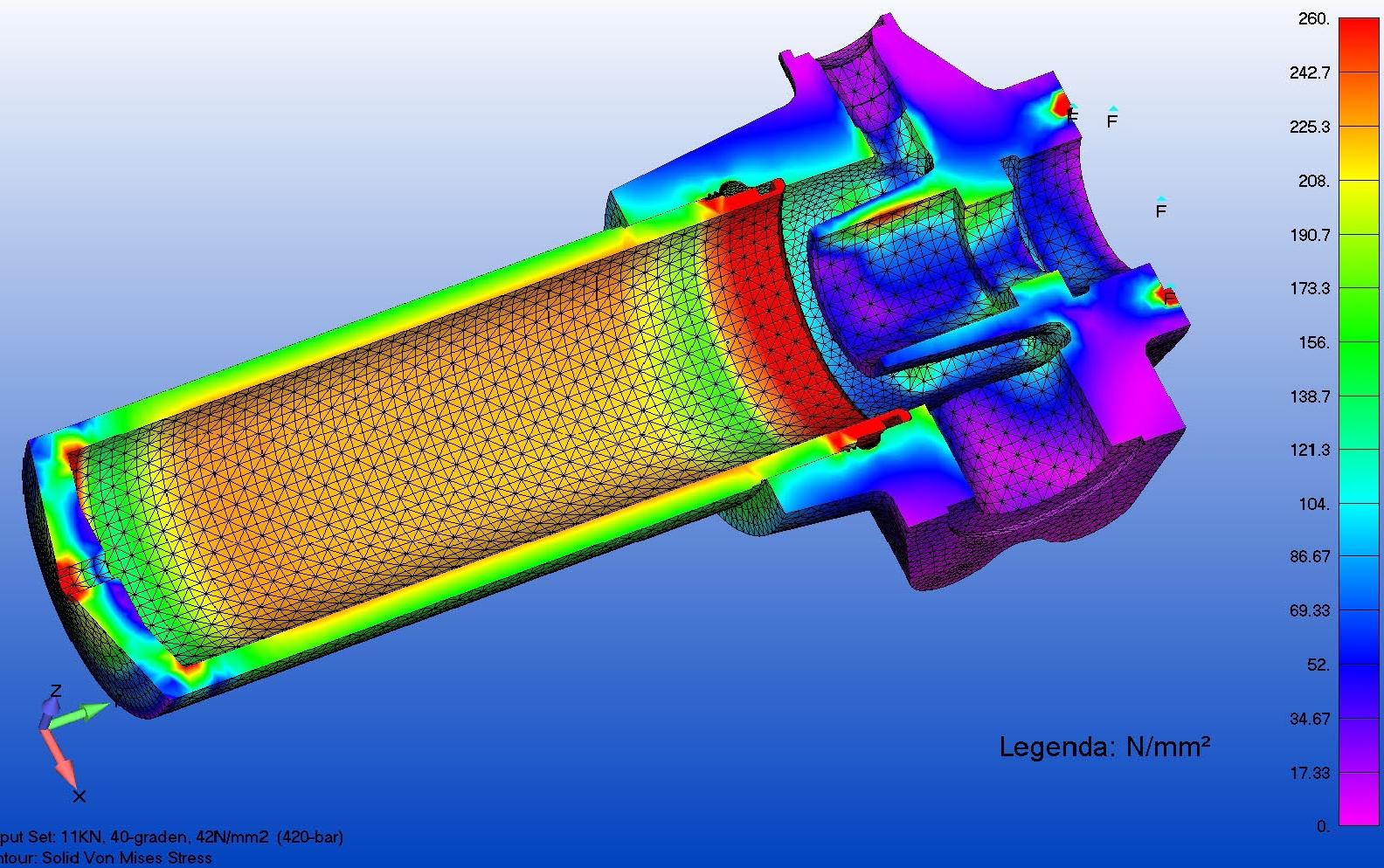

Good engineering work lays the foundation for a stable production process. Dematech collaborates with you in an early stage concerning the design of metal parts and assemblies. We consider function, load, environment, and maintenance, and translate that into a smart product.

Whether it concerns a new concept, a redesign of an existing part, or the engineering of a prototype for serial production: we ensure that your design is ready for production. In doing so, we take into account available machines, tolerances, and the desired production volume.

Balance between manufacturability, cost price, and functionality

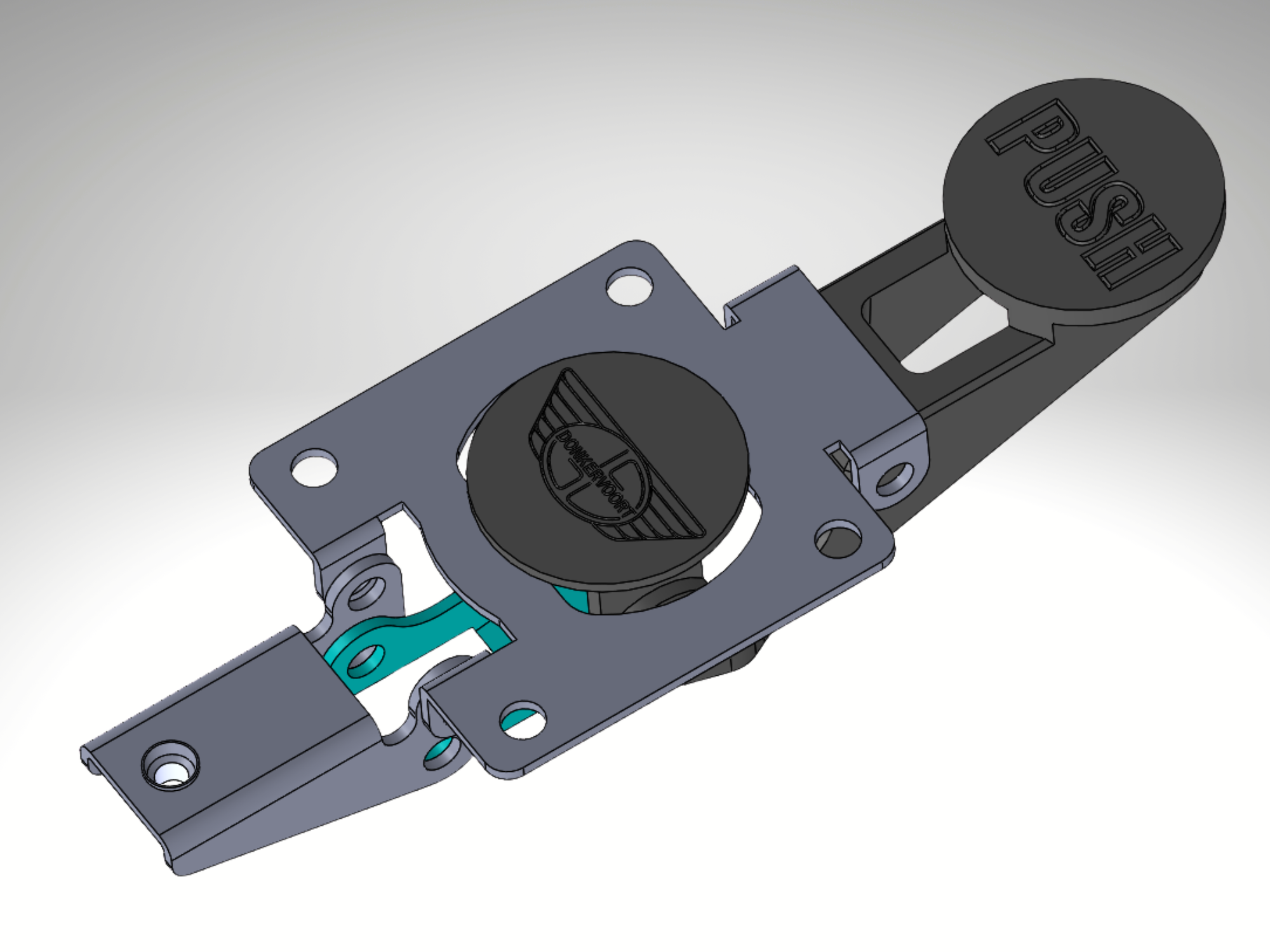

A good design is not only strong and functional, but also manufacturable and affordable. Dematech applies design-for-manufacturing: we examine how a part can best be produced with as few operations, actions, and error possibilities as possible. This way, we balance functionality, cost price, and lead time.

Together, we analyze alternative geometries, material choices, and tolerances. Small design adjustments can have a major impact on machining time, sheet metal development, assembly time, or post-processing. By making these choices in advance, you save time and money later in the chain.

Co-engineering in practice

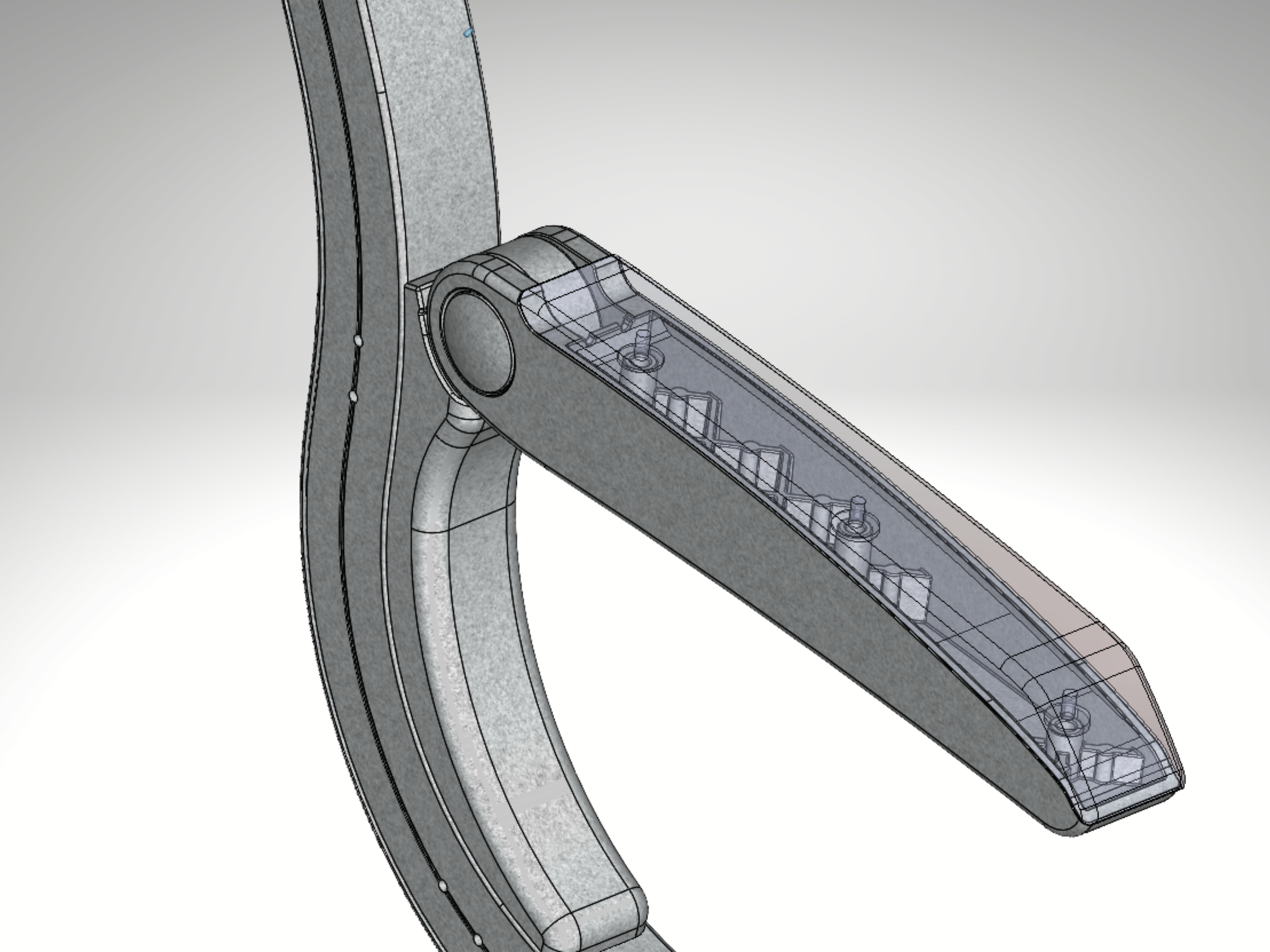

We join your engineering or R&D team and work together on customer-specific solutions. From the initial sketch to the final model, we contribute ideas about functionality, assembly, service, and lifespan.

Digital models & documentation

We deliver designs as a 3D model and 2D drawing, including bills of materials and any specifications for surface treatments and assembly. This way, production can start immediately and the documentation remains clear and complete.